> ACCENT en > Nr 10 Sept. 2006 Africa's emissions > R: New Technologies

|

|

|

New Technologies

A plant oil stove for developing countries

Scientific studies as carried out, for example at the University of Berkeley in California, show that the use of clean fuels in households of developing countries could save millions of lives. Additionally it would have positive impacts on the greenhouse gas budget.

|

About 1.6 million people, primarily women and children, die each year from lung diseases, which are related to the inhalation of emissions from domestic fires. Of these, 400,000 fatalities occur in Sub-Saharan Africa.

With increasing urbanisation, fuel use may slowly shift from firewood to charcoal. It would be possible to increase the efficiency of charcoal production. But a more reasonable solution would be to use fuels with lower emissions and a higher heat value like gas and oil products.

This needs not necessarily be a petroleum based fossil fuel, but may also be plant oil from sustainable production.

|

|

|

|

|

1. Three stone stove in Leyte / Philippines © BSH

|

|

|

|

|

2. Plant oils range in their heat value between charcoal and kerosene. Please click the graph on the left in order to enlarge.

However, the use of such fuels should not require a big investment in an expensive stove. The typical small stove in Africa costs about 4-6 US$ and it should not be based on a technology which requires frequent repair.

|

|

|

|

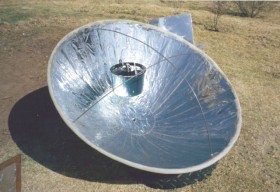

An example of a nearly emission free stove, which is often presented, is the solar cooker. Solar cookers however depend on sunlight. They can be suitable for kitchens of boarding schools or comparable canteen kitchens. But they are hardly applicable for the private household in the village, where the meal is prepared after the family come back from work in the evening and direct solar radiation is not available anymore.

|

A test in Leyte

4. The province of Leyte is one of the Philippine islands. In 2000 Leyte had a population of about 1.57 million inhabitants, living on an area of 5700 square kilometres. Leyte (279 inhabitants/sqkm) has a slightly higher population density than the rest of the Philippines (255 inhabitants/sqkm) or Germany. Click on the map on the right in order to see the location of Leyte.

|

|

|

|

|

|

7. Protos plant oil stove © BSH

|

|

|

A potential alternative is an easily producible and comfortably operated stove, which can be driven by unrefined oil from plants. Such a device has been developed by the company BSH Bosch und Siemens Hausgeräte GmbH after basic research of the University of Hohenheim and in cooperation with other universities. It has been successfully tested at Leyte island in the Philippines. |

The price for a litre of refined coconut oil is about 35 Philippine Pesos (PHP), which is about 60 EUR Cents. You can get a litre of unrefined oil for 28 PHP (about 48 EUR Cents). The stove is constructed in a way that it can also be used with the unrefined oil. Some residues, which may form during evaporation, can easily be removed with a brush.

on the right: 8. Coconut plantations deliver enough oil in Leyte © BSH

|

|

|

|

|

|

9. Training with the plant oil stove © BSH

|

|

|

Calculation of oil demand

The oil demand for the stove of an average family (which is 5.2 persons in the Philippines) is about 100 litres of oil per year. This demand can be covered by an area of significantly less than 1/10 hectare or less than 25 x 40 m, the area of a big garden. Leyte has large coconut plantations. One third of the harvest would deliver enough oil for all inhabitants of the island.

|

How does the plant oil stove work?

The plant oil stove is a modified version of a pressure stove which is rather common in the tropics and sub-tropics. These stoves are usually made in order to be used with petroleum / kerosene. The fuel is stored in a vessel in which slight pressure is generated with the help of a hand pump. From this, the fuel is pumped into a steam chamber, where it is thermally gasified and comes out through a nozzle.

|

|

|

|

|

10. Burner from above © BSH

|

|

|

|

|

13. The stove in use © BSH

|

|

|

The jet is mixed with the surrounding air and the fuel-air-mixture burns up in the combustion area. In order to start the burning process a small amount of ethanol is lit in a pre-heating pan. This way the evaporator is brought to the required temperature. The device developed by BSH works in a similar way but is modified for use with the more viscous and less inflammable plant oil.

|

Outlook

For a wider dissemination of such a stove further studies are necessary and barriers have to be overcome. In which regions is the sustainable production of sufficient amounts of plant oil possible? What are the ecological and agroeconomical conditions? What infrastructure is required in order to produce the oil close to the demand regions and to bring it to the markets? Is it possible to produce the stove for a price acceptable for the average African household?* Can the locals be convinced everywhere as easily as in the Philippines to test the new device?

Or, alternatively ... would it be sufficient in some developing countries to improve the sustainability of forest management, to continue firewood use and to equip the common fireplaces with a chimney? These are open questions for the future.

|

|

|

|

|

14. Children in Leyte. How will the next generation cook? © BSH

|

|

The Protos plant oil cooker is offered on the Philippines for a price of around 30 EUR (38 USD or 1900 PHP, as of September 2006). The production price will be slightly higher by the time this article appears. But according to expectations of the company it can be produced cost-effectively with increasing demand and optimisation of materials.

Author: Elmar Uherek

Acknowledgement:

We thank the BSH Bosch und Siemens Hausgeräte GmbH for the provision of photos (marked with © BSH) from their field test in Leyte as well as for detailed information and ideas during the development of this article.

|

> ACCENT en > Nr 10 Sept. 2006 Africa's emissions > R: New Technologies

> ACCENT en > Nr 10 Sept. 2006 Africa's emissions > R: New Technologies