> ACCENT en > UQ 3 May 07 Cars and ozone > F: Particle filters

> ACCENT en > UQ 3 May 07 Cars and ozone > F: Particle filters

|

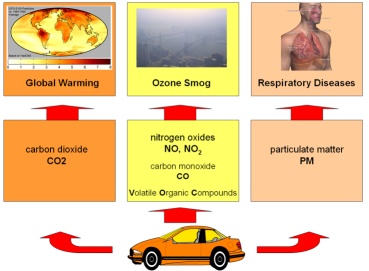

Diesel engines and particle filtersSpeaking about car exhaust, we have to consider basically three types of emission: 1) carbon dioxide |

|

Carbon dioxide (CO2) is the greenhouse gas, which contributes most to human induced global warming. It is not an immediate problem for our health but for the climate system. Gaseous emissions may come from evaporated or not completely burnt fuel. We call them volatile organic compounds VOC, consisting of hydrocarbons or oxidised hydrocarbons. Other gases are products of the combustion process: nitrogen oxides (NO and NO2 = NOx) and carbon monoxide (CO). They are not healthy and they cause indirect problems because they cause ozone smog in particular in summer. Particles are formed in larger amounts in diesel engines, for example when the car accelerates. They consist of soot and unburnt compounds in the fuel condensing on soot or tiny sulphate particles. Particles are a larger problem in diesel engines, because the engines inject varying amounts of fuel into always the same amount of hot air. If the mixture is oversaturated with fuel, particles form easily. |

|

Particle filter technologies CRT (Continuous Regenerating Trap) and DPX (filters with a noble metal layer) work based on the so-called “wall flow principle”. In this process, the exhaust gas goes into a number of dead-end channels. The unburned carbon deposits itself in the channel and the gas portion of the exhaust passes through the porous walls, which have a defined pore structure. |

Alternatively the “flow through principle” can be used. Flow through filters consist of metal fibers or films the gas passes along and particles adhere on the walls. An electrical current can be passed through the uniform material to heat the core for regeneration purposes. Or it is regenerated with the CRT technology by hot gas. |

|

|

Regeneration systems For the regeneration (= cleaning) of a wall flow system the deposited soot and particles have to be burnt at high temperatures of more than 600°C. This is much if we consider that the temperature can go down to about 200°C while driving in cities. The regeneration temperature can be reduced to 500 – 550°C with the help of an additive. This temperature is normal on the highway or can be generated by an additional injection of fuel. But additives are complex and less comfortable to handle. |

|

A solution for continuous soot removal is the “continuous regenerating trap” (CRT), which are often used in buses. In these emission reduction systems, the exhaust gas passes an oxidising catalytic converter. Here, CO and organic compounds are nearly completely oxidised. Such emissions are in any event minor in diesel engines. Nitrogen compounds are primarily oxidised to NO2, because the NO2 reacts with the soot forming CO2 at a temperature between 200°C and 450°C. |

A disadvantage of the systems is that NO2 is usually produced in excess. The NO2 fraction in the exhaust gas may be in the range of 5% before the catalytic system and 20% after. The system reduces particle emissions at the cost of higher NO2 emissions, which in turn promote the formation of ozone smog. |

|

|

So-called Selective Catalytic Reduction systems (SRC catalysts) might become a solution for this problem. SCR uses a reductant that is added to the exhaust gas in front of the catalyst. The most common way for the SCR-reaction is the use of ammonia that can be generated onboard by bringing urea into the hot exhaust gas stream. By this means nitrogen oxide emissions can be significantly reduced. But also this technology is complicated and the reduction rate depends on the conditions. Diesel particle filters and SCR can be combined. |